Inside the Seawind Factory: A First Look at the New Seawind 1270

January 23, 2026

AVAILABLE FOR IMMEDIATE RELEASE…

Sydney, Australia – 23 January 2026

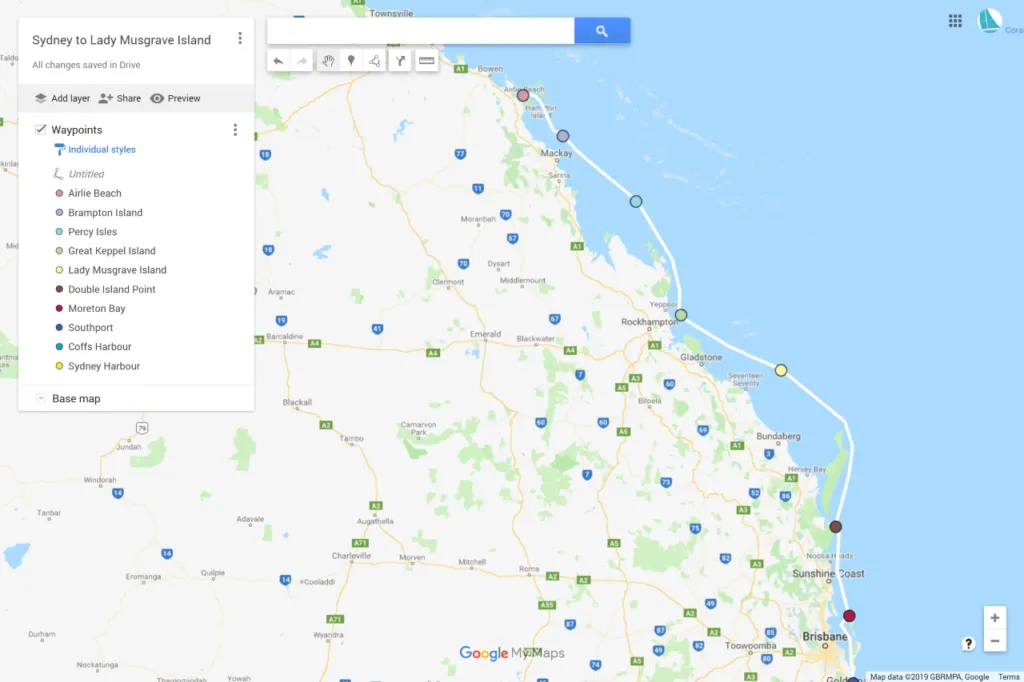

Multihull enthusiasts are getting an exciting glimpse into the future of performance cruising as Seawind Catamarans advances construction of the very first Seawind 1270. On a recent tour of the Seawind production facility in Vietnam, we joined a new Australian owner walking through his customisation options and witnessing the craftsmanship behind this next generation model.

One of the unique pleasures of commissioning a new build with Seawind is the handson experience. Customers can walk the factory floor, explore vessels in different stages of completion, and refine the details of their own boat with guidance from Seawind’s technical team. With dozens—sometimes hundreds—of decisions to make, from layout preferences to equipment upgrades, this process offers an intimate involvement rarely found in modern boatbuilding.

Engineering Evolution of the 1270

Leading the technical walkthrough, Seawind Technical Manager James Sganzerla outlined the major design changes that distinguish the 1270 from the popular 1260. The most noticeable updates begin with the hull. The new model features a slightly wider and flatter hull form with reduced rocker and sharply defined square chines at the transom. These refinements enhance flotation, boost sailing performance, and significantly increase wingdeck clearance. A wider transom platform also provides easier boarding and improved usability around the marina.

Inside the hulls, the raised and flatter deck profile has created a dramatic improvement in interior volume. Forward cabins now offer greater headroom, generous storage, and the ability to sit upright comfortably in bed—an upgrade over the more compact spaces in previous models. Modular furniture components are moulded and infused outside the hull, then craned into position and laminated in place for consistent alignment and strength.

Smarter, Stronger, and Lighter

A major engineering focus for the 1270 has been strategic integration of carbon fibre. Key structural bulkheads, hull stringers, and highload zones now incorporate carbon uni-directionals to maximise stiffness, reduce weight, and enhance overall performance. This reengineering process represented months of collaboration between Seawind and its naval architects and ensures the 1270 is optimised for today’s larger rigs and higher righting moments.

At the bow, Seawind has introduced a composite longeron and integrated forebeam, replacing the older aluminium crossbeam and folding bowsprit. This new structure not only increases rigidity but allows cruisers to keep their screecher permanently rigged on a fixed tack point.

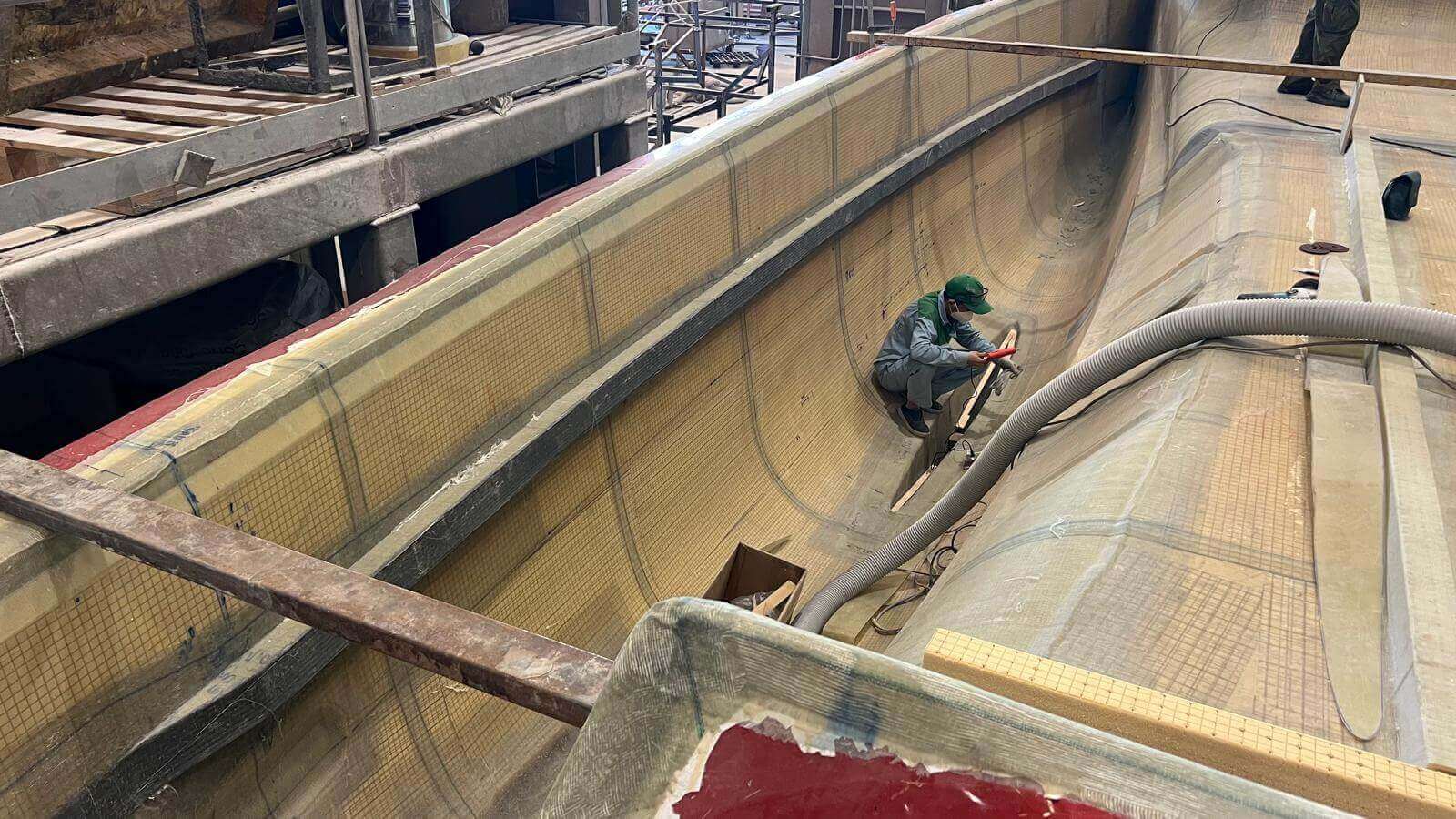

Precision Resin Infusion and WorldClass Facilities

The Vietnam factory utilises advanced resininfusion methods for the hulls, decks, and most major structural components. This process ensures a precise resintofibre ratio, eliminates voids, reduces excess weight, and produces stronger, more consistent parts. Each section of the deck and hull is produced from detailed kits, with exhaustive layup schedules and vacuumtesting to ensure flawless execution.

The scale of the facility is equally impressive: over 500 staff across two sites, full gantrycrane systems, climatecontrolled lamination bays, and adjacent water access for efficient launching.

InHouse Craftsmanship

One standout feature of Seawind’s approach is how much of the work is kept inhouse. From mast fabrication to upholstery, rigging, and even intricate timber joinery, Seawind manages nearly every step internally. The timber shop in particular is a highlight—producing solid timber trims, realveneer cabinetry, and detailed inlays with a level of craftsmanship that sets Seawind apart from most production yards.

Visit the Factory, Explore Vietnam

For buyers like the future 1270 owner touring with us, pairing a factory visit with a customised holiday is an unforgettable experience. Whether cruising the Mekong Delta, exploring Saigon’s rooftop dining scene, or venturing north to Halong Bay and Hanoi, Vietnam offers incredible travel opportunities alongside the excitement of seeing your catamaran come to life.

For more details on the Seawind 1270—including pricing, build slots, and delivery timeframes—follow the link HERE .

About Seawind Catamarans

Founded in Australia and now manufacturing in Vietnam, Seawind Catamarans has built a reputation for producing high-quality, performance-oriented cruising catamarans. With models ranging from 35 to 43 feet, Seawind focuses on bluewater capability, innovative design, and exceptional value. The company’s boats have completed countless ocean crossings and circumnavigations, establishing Seawind as a trusted name in offshore sailing.

About Multihull Central

Exclusive distributors for Seawind Catamarans in Australia and New Zealand, Multihull Central are specialist catamaran reseller and offers a ecosystem of services to help new boat owners go cruising, from sail training, bareboat holidays, Cruz Club, charter management, launching and commissioning, warranty support and after sales service.

For media contact Brent Vaughan | M: 0418 670 751 | E: brent@multihullcentral.com